Centrifugal Industrial Fans

Applications for industrial blowers include high airflow volumes, manufacturing process exhaust, grease-laden, and emergency or continuous high-temperature exhaust. Prior to shipment, each fan assembly is factory run and tested to meet acceptable vibration criteria. A wide range of protective coatings is available. Construction is aluminum or stainless steel (airstream only). Backward-inclined or higher efficiency airfoil centrifugal wheels are available with heavy-gauge steel, fully welded or lock-seam housing.

OVERVIEW

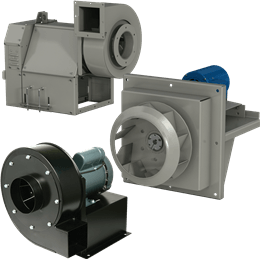

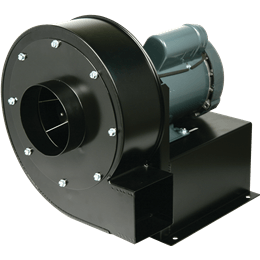

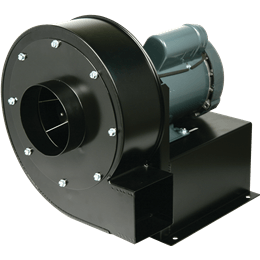

FPB

Model FPB is a pressure blower that uses a radial aluminum blade wheel providing efficient operation and spark resistant construction. Housing design is fully rotatable and constructed of steel with a baked polyester coating. All models are direct drive, arrangement 4 with wheels directly connected to the motor shaft.

- 200 to 2,500 cfm

- Up to 9.5 in. wg

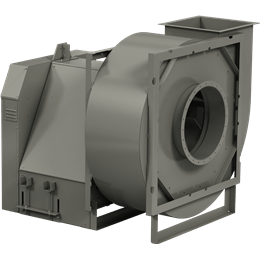

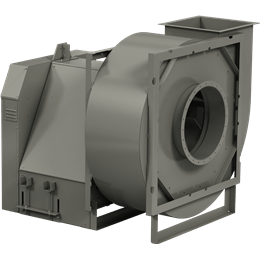

IP

Wheel Types:

- Air handling - clean and light material-laden air

- Open radial - abrasive dust like grinding and buffing wheel exhaust, fume exhaust, and to convey granular materials, sawdust or wood chips

- Back plated/wool - long, fibrous and stringy material such as wood shavings, yarn or paper trimmings

- 200 to 143,000 cfm

- Up to 32 in. wg

- Spark A and B resistant construction available

AMCA licensed for FEI & Air Performance

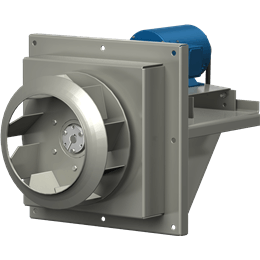

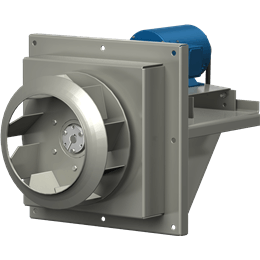

PLG

In most instances, plug fans are unhoused and rely on the plenum space around the backward-inclined centrifugal wheel to direct airflow as required in the system. Model PLG is available in belt or direct drive with steel, aluminum or 316 stainless steel constructions.

- 900 to 71,000 cfm per fan

- Up to 8 in. wg

- AMCA Spark B or C resistant construction (available)

- 800°F maximum operating temperature (optional)

-

Catalogs

-

Instruction Manuals

-

Specifications

-

Drawings

-

STATIC MODEL DOWNLOAD3D CAD2D CAD

-

FPB

FPB IP

IP PLG

PLG

-

-

Application Information

- Videos

-

Other Product Information

-

Warranty

-

Project Profiles